Who we are

WHY CARCO PRP?

Fast reaction

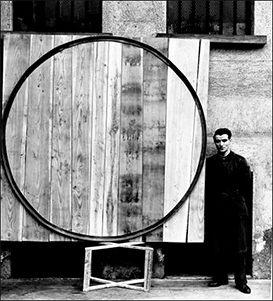

From small to giant sizes

Worldwide network

Molded and machined seals

Technical support

Endless and split seals

More than a century of experience

From leather seals for the first hydropower plants to modern sealing solutions. This is the evolution of CARCO – PRP in more than a century, manufacturing rotary shaft seals and hydraulic seals for all diameters, in fabric reinforced elastomers and in thermoplastic polymers. We keep greatest attention to quality since we dedicate to challenging and critical applications, with no room for mistakes.

CARCO - PRP

Today CARCO – PRP is part of a group of companies specialized in the design and manufacture of seals, employing more than 800 people and with production sites in Italy, the USA and Canada.

We offer our products through a global network of CARCO – PRP sales offices and authorised distributors

Fast

Short delivery time is part of our image, even when we deliver large diameter seals for metal forging presses or for giant wind mills or for ceramic presses. We are proud to deliver on time a very high percentage of the orders.

Expertise

We are specialized in a large variety of applications: to satisfy the customer’s requirements we need to know deeply the machinery in which our seal is fitted. Our technical department specifies the suitable seal profile and material to offer the longest seal life and prevent costly machine shutdown. Our technical support includes the definition of metalwork finishing, lubrication system and future maintenance.

Production

We dispose of one the largest hydraulic press in the world for the vulcanization of seals in fabric reinforced elastomers (3 mt.); a long serie of presses cover the complete size range. The department of termoplastics machining disposes of several CNC lathe machines up to 3 meter diameter. Our technology of hot and cold bonding enables the production of giant seals.

Research and development

CARCO – PRP engineers can design customized seals based on working conditions provided by the machine manufacturers. With finite element analysis we predict the behaviour of the seal, with our test rigs we explore new projects and with our laboratory we develop new materials and verify the quality of the raw materials.